"Building one’s own house can be a source of extreme danger," says French designer Philippe Starck. "We all know when it starts, but we never know when it is going to end or how much it will cost in the end."

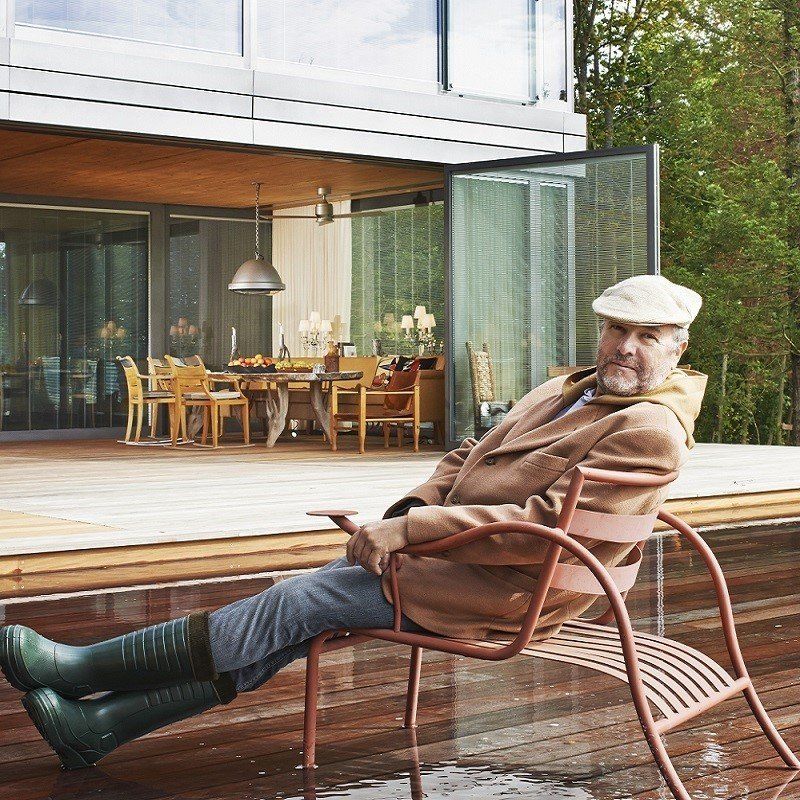

The new, ecologically minded P.A.T.H. prefab prototype-designed by French designer Philippe Starck in tandem with the Slovenian prefab homebuilder Riko-was recently built for the first time at a test site in Montfort l’Amaury near Paris.

Considering his background, and the fact that this industrial designer’s work has touched nearly every facet of the built environment, it’s no surprise that his solution to home buying was to industrialize the process. But his new P.A.T.H. prototype-designed in tandem with the Slovenian prefab homebuilder Riko, and recently built for the first time at a test site in Montfort l’Amaury near Paris-is as ecologically sound as it is precisely engineered.

The P.A.T.H. system isn’t just another glass box. Customization technology at the Riko factory allows potential homeowners to choose from 34 variations on a theme, with alternating sizes (roughly 1,500-3,800 square feet), sides (wooden walls to an all-glass shell) and shapes (cornice, flat, or pitched roof). The price per square meter (upwards of $530 per square foot) certainly isn’t inconsequential, but as Starck says, "It’s not [just] about better design, it’s all about better quality."

"P.A.T.H. is a positive energy house, which produces 50% more energy than it consumes" says Starck. "The positive energy that isn’t consumed can return to the local electric grid."

"P.A.T.H. is a positive energy house, which produces 50% more energy than it consumes," says Starck, referring to numerous features that can be added to any model, such as wind turbines and solar cells. "The positive energy can be sent back to the local electric grid."

The eco-engineering begins with the exterior, made from sustainably harvested wood and wrapped in a triple-glazed glass envelope with options for wind turbines and DualSun solar panels to provide energy, heat, and water. Modular, high-efficiency SPEETA wood stoves provide additional low-cost heating. According to Starck, it takes six months from order to open house.

The architectural tour de force of the home, according to Riko CEO Janez Skrabec, is the cornice-shaped roof, built from a series of light fiberglass modules that can be disassembled, recycled, reshaped, or reused. In addition to conceling elements such as the wind turbine from view, it also functions as a green roof. "The hollow 'sinks' of the cornice act as flowerpots and are able to host plants, which can be watered with the help of rainwater collection systems," says Skrabec. "Furthermore, the large arches of the roof provide shelter and cast additional shade on the rooms below, combining a number of benefits in a single solution."

"P.A.T.H. houses are built like how we assemble Legos," he says. "All the elements of the houses are prefabricated in Riko’s factories and then assembled on the building site."

"With P.A.T.H., we wanted to enhance coherence and synergy between the architecture and the technical," says Starck. "The objective of our project was to integrate the energy system in the core of the building process. We worked very hard on the quality of the building envelope."

Customization technology at the Riko factory allows potential homeowners to choose from 34 variations on a theme, with alternating sizes (roughly 1,500 to 3,800 square feet), sides (wooden walls to an all-glass shell) and shapes (cornice, flat, or pitched roof). The price per square meter (upwards of $530 per square foot) certainly isn’t inconsequential, but as Starck says, "It’s not [just] about better design; it’s all about better quality."

"With P.A.T.H., I wanted to provide the community with the best product, in terms of quality, technology and durability," says Starck. "Durability and the notion of heritage, which were almost taboos in the ‘70s and ‘80s, are essential today."

"With P.A.T.H., I wanted to provide the community with the best product, in terms of quality, technology and durability," he says. "Durability and the notion of heritage, which were almost taboos in the 70s and 80s, are essential today. In order to guarantee longevity, we must build at the right price, which forces us to arbitrate between various items without being a low-bidder or falling into the opposite, excess. When we pay for what’s visible, we inevitably cut out what is invisible but yet fundamental: quality. I did not want to impose anything to our customers: the architectural possibilities are very flexible."

Starck says that Riko’s experience in prefabrication played an important role in the design and layout of the home system. "The prefabrication process, based on laser-cut technology, allows a surgical precision," he says. "Riko’s expertise enables us to minimize the risks and bad surprises." In the design, the electrical system is hidden behind wooden panels.

Tropical Boho Homes With Beautiful Vignettes & Vistas

Two tropical boho home designs, featuring swimming pools, cozy lighting schemes, interior archways, natural accents, and beautiful decor vignettes.

![A Tranquil Jungle House That Incorporates Japanese Ethos [Video]](https://asean2.ainewslabs.com/images/22/08/b-2ennetkmmnn_t.jpg)