On a wooded hillside in the Mexico City colonia of Bosques de las Lomas, Taller Aragonés has erected a prototype of the Pi Home to showcase its ingenious, fully customizable modular construction system. The prefab comes flat-packed in boxes and can be assembled in 45 days without the help of heavy machinery.

Buyers of the Pi Home can fully customize the interior, from furniture selection and fabrics to the veneer of the wall panels.

Lightweight, intuitive to assemble, and inexpensive to ship, the Pi Home uses extrusion-die aluminum framing that’s anchored with rebar to the ground or a poured concrete foundation. Like a Lego set, a network of steel doughnuts spans lengths of up to 30 feet to support the structure. Aluminum studs link seamlessly to joists, and the exterior cladding is clipped onto the frame. It’s a method that could, in principle, be extended to 45 feet. Able to be shipped anywhere, the system holds potential for single-family homes as well as larger projects, such as social housing.

The aluminum joists and studs plug into series of steel doughnuts to secure the structure.

The Pi Home is adaptable to different site conditions and engineered to withstand the earthquakes common to Mexico City.

"It’s important to emphasize this being not only a modular system, but a construction system, so it can transform according to the site’s topography and dimensions," says Rafael Aragonés, son of architect Miguel Aragonés and an associate in his studio. "If you need to adapt it for a particular project or landscape, you’re easily able to adjust the construction system."

Double-glazed windows facing south provide both insulation and adequate heat gain for the cooler climate of the city’s higher altitude in Bosques de las Lomas.

The homes come move-in ready with appliances, furniture, and finishes chosen by the owner.

In the Pi Home prototype, the walls and floors are composed of MDF with the wood veneer clipped to the aluminum structure.

Insulation between the exterior cladding and interior walls ensures a high energy-efficiency rating, which can reach as high as R30 depending on its thickness.

The Bosques de las Lomas model is a relatively luxe version, furnished with top-of-the-line appliances and finished with high-quality materials. Even so, Aragonés says, the Pi Home’s aluminum frame, speed of assembly, and lower shipping costs means that it’s about a third of the cost of a typical construction—making it an exemplary modern home affordable to moderate-income earners.

The rear curtain wall system opens to an outdoor patio raised above the wooded landscape.

Retractable screens allow for shade and privacy in the living area.

A wraparound veranda bordered with glass offers additional outdoor space.

Not only that, the Pi Home surpasses traditional home design through its impressive energy efficiency. The walls and joists have thermal and waffle insulation packages that meet California’s high R22 sustainability standard, achieving a complete thermal break to prevent leakage of heat through the structure. The windows are all double-glazed. And aluminum is one of the most easily and widely recycled materials, giving the house an especially circular life cycle.

"You have all of this midcentury inheritance, but truly, when you visit these houses in California, it was all very aesthetic, but it was unlivable on a hot or cold day," says Aragonés. "We have to take the step and accomplish having efficient thermal living inside the house."

The main bedroom on the second floor takes advantage of the curtain wall's openness.

Recessed lighting gives the space a warm glow at night.

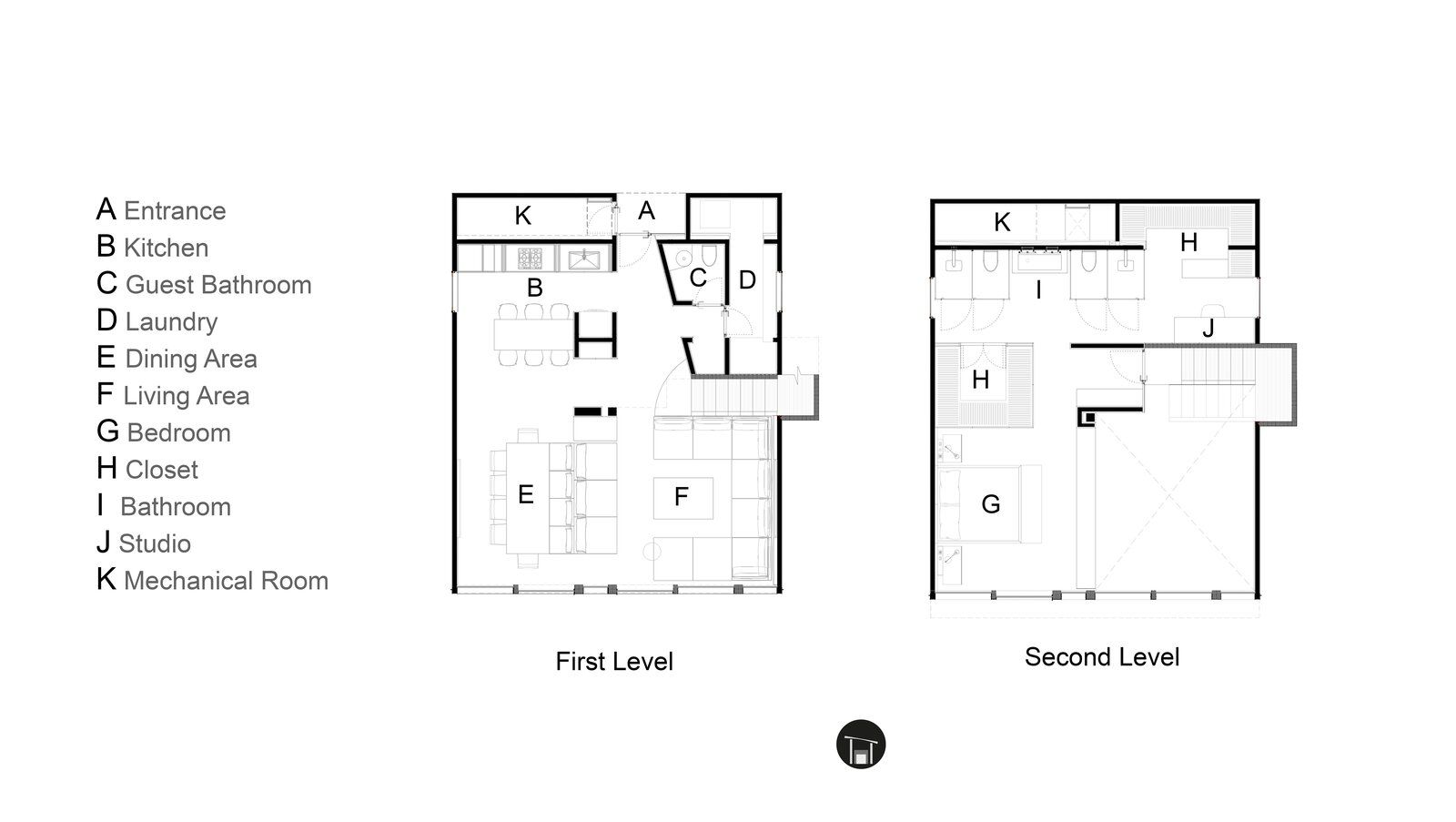

Pi Home prefab floor plan

The Pi Home has received an international patent in Switzerland for the first-of-its-kind structure for aluminum houses. Taller Aragonés expects to complete the International Code Council building certification process in the coming months and plans to market the house in California, New York, and Texas.

Tropical Boho Homes With Beautiful Vignettes & Vistas

Two tropical boho home designs, featuring swimming pools, cozy lighting schemes, interior archways, natural accents, and beautiful decor vignettes.

![A Tranquil Jungle House That Incorporates Japanese Ethos [Video]](https://asean2.ainewslabs.com/images/22/08/b-2ennetkmmnn_t.jpg)